Did you know many construction accidents happen because of a few common mistakes? Understanding the causes of construction accidents is important for keeping everyone safe on the job site.

Whether you’re a worker or a project manager, you know that even a small lapse in attention can lead to serious injuries or worse. This article will explore the most common causes of construction accidents and show how sticking to safety rules can help prevent them. If you’re worried about safety on-site or know someone affected by an accident, this guide will provide useful insights and practical tips to protect your team.

Understanding the Root Causes of Construction Accidents

Identifying what leads to construction accidents is the first step in preventing them. This section will cover causes that can put safety regulations at risk and lead to accidents on the job site. Understanding these root causes helps us create a safer environment for everyone involved.

Unsafe Working Conditions

A construction site that fails to manage risks effectively is prone to accidents. Factors contributing to unsafe conditions include:

- Poor Site Maintenance: Remove clutter and debris promptly and ensure surfaces are even to prevent trips and falls.

- Inadequate Safety Gear: Proper helmets, gloves, and harnesses are vital to reduce injury risks.

- Hazardous Weather: Adapt work practices during adverse weather to maintain safety.

Human Error and Negligence

A lack of training or focus can lead to preventable mistakes. Common issues include:

- Inexperience or Fatigue: Ensure all workers are adequately trained and rested.

- Neglecting Safety Protocols: Emphasize the importance of following all safety steps, regardless of project deadlines.

- Improper Equipment Handling: Regularly train and retrain employees on correctly using tools and machinery.

Equipment and Machinery Failures

Frequent inspections and proper maintenance are essential to prevent machinery and equipment failures, including:

- Conduct Regular Safety Checks: Inspect all large equipment, such as cranes and forklifts.

- Maintain and Inspect Tools: Regularly check power tools for damage to prevent unexpected malfunctions.

- Train Equipment Operators: Ensure all operators receive proper training to reduce the risk of accidents.

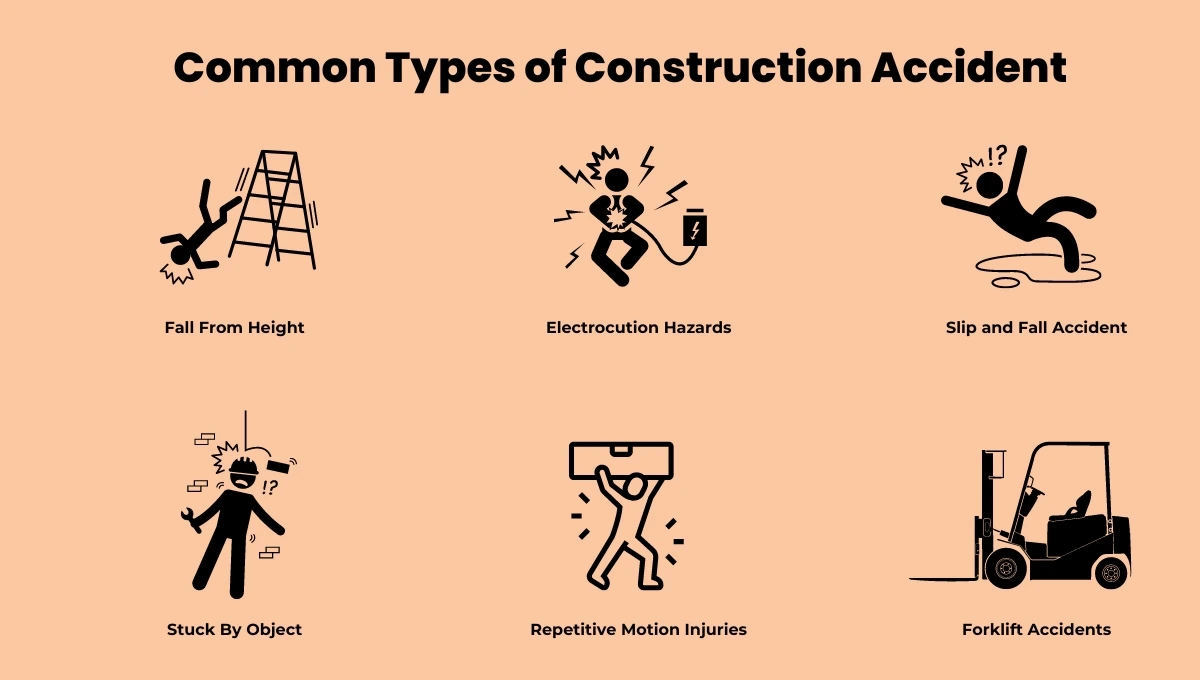

Preventing Specific Accident Types on Construction Sites

Recognizing and preparing for various accident scenarios is essential for safety. Here are some effective strategies and OSHA compliance tips to help reduce the risk of these common construction accidents.

Falls from Heights

Implement these measures to prevent falls, a leading cause of severe injuries on construction sites:

- Use Safety Harnesses: Always secure workers with harnesses when working at heights.

- Install Guardrails: Fit guardrails on all open sides and elevated platforms.

- Check Ladders and Scaffolding: Regularly check that all structures are stable and secure.

Struck by Falling Objects

Minimize risks from unsecured tools and materials:

- Wear Hard Hats: Hard hats are required in all active zones.

- Secure Loads: Fasten all materials and tools securely when working at heights.

- Install Overhead Safety Barriers: Utilize nets and protective barriers in areas with overhead hazards.

Electrocution Hazards

Adhere to these practices to reduce electrocution risks:

- Maintain Safe Distance from Power Lines: Always clear and mark hazardous areas.

- Inspect Electrical Tools: Regularly check for damage or faults.

- Install Ground Fault Circuit Interrupters (GFCIs): Place GFCIs in all moisture-prone areas to prevent electrical mishaps.

Caught-In/Between Accidents

These accidents occur when workers are trapped or crushed between heavy machinery or materials. The following measures can prevent such incidents:

- Implement Machine Guarding: Protect against contact with moving machinery parts.

- Define Safety Zones: Mark no-access zones during machinery operation.

- Promote Crush Point Awareness: Train workers on identifying and avoiding crush points.

Slip, Trip, and Fall Hazards

Prevent common slips, trips, and falls with these precautions:

- Maintain Clear Walkways: Maintain cleanliness and remove obstacles.

- Use Anti-Slip Mats: Place the mats in spill-prone areas.

- Ensure Proper Lighting: Ensure adequate lighting to avoid accidents in poorly lit areas.

Forklift and Heavy Equipment Accidents

Ensure the safe use of heavy machinery:

- Require Operator Training: Only certified personnel should operate heavy equipment.

- Perform Daily Equipment Inspections: Check for operational safety each day.

- Establish Dedicated Operating Zones: Keep untrained personnel out of operational areas.

Repetitive Motion and Overexertion Injuries

Implement ergonomic practices to prevent these types of injuries:

- Equip Ergonomic Workstations: Equip workstations with tools that minimize physical strain.

- Schedule Regular Breaks: Reduce fatigue and risk of injuries with scheduled breaks.

- Teach Proper Lifting Techniques: Educate on safe lifting practices to prevent back and muscle injuries.

Legal and Financial Implications of Construction Site Accidents

When accidents occur on construction sites, they bring not only physical consequences but also complex legal and financial challenges. Understanding who is responsible and what actions to take can help construction workers secure their rights and compensation. This section will explore liability, immediate steps after an accident, and how workers can claim compensation.

Who Is Liable for Construction Accidents?

Identify who is responsible for maintaining safety and enforcing standards:

- Enforce Contractor Responsibilities: Contractors must ensure compliance with all safety regulations to prevent accidents.

- Maintain Workplace Liability Insurance: Companies use insurance to protect workers and businesses from financial burdens.

- Address Third-Party Liability: Manufacturers or subcontractors can be accountable for defective equipment or faulty practices leading to accidents.

Steps to Take After a Construction Accident

After a construction accident, victims must take immediate actions to protect their rights and secure compensation:

- File an Accident Report: Document the accident officially without delay.

- Adhere to the Emergency Response Plan: Seek immediate medical attention and follow established emergency procedures.

- Collect Evidence: Compile photographs, witness statements, and medical records to support your compensation claim.

Compensation for Injured Workers

Handling the compensation process to ensure timely and adequate benefits:

- Submit Workers’ Compensation Claims: Submit claims promptly for medical expenses and lost wages.

- Complete the Injury Claim Process: Accurately complete all necessary documentation to avoid delays.

- Explore Legal Options: Consider legal action if negligence played a role in the accident.

Enhancing Safety on Construction Sites

Keeping construction sites safe means focusing on worker safety training and using the right safety gear. Emphasize the importance of training, appropriate safety equipment, and regular inspections to prevent accidents.

Comprehensive Safety Training

Ensure training programs meet OSHA requirements and all workers are familiar with safety protocols:

- Tailor Relevant Training: Tailor training programs to specific job hazards.

- Require Safety Certification Programs: Certifications validate the worker’s safety knowledge.

- Provide Regular Safety Updates: Regularly update training to reflect the latest safety standards.

Personal Protective Equipment (PPE)

Maximize protection with appropriate safety gear:

- Match PPE to Job Hazards: Ensure PPE is appropriate for the specific hazards of the job.

- Conduct Regular Gear Inspections: Routinely check gear for wear and damage.

- Enforce PPE Compliance: Ensure all personnel adhere to PPE guidelines.

Regular Equipment Maintenance and Inspections

Prevent accidents through diligent maintenance and inspection practices:

- Implement Maintenance Schedules: Establish regular maintenance routines to prevent equipment failures.

- Conduct Safety Inspections: Confirm that all equipment meets safety standards before use.

- Document Inspection Results: Maintain records of all inspections and repairs for compliance and review.

Conclusion: Building a Safer Future in Construction

By understanding the root causes of construction accidents and implementing rigorous safety protocols, we can significantly reduce risks and enhance site safety. Prioritizing safety training, enforcing the proper use of personal protective equipment (PPE), and performing regular equipment inspections are all key actions to prevent accidents. Adhering to legal guidelines and preparing for accidents ensures workers can secure proper compensation and support after an incident. Even with safety measures, accidents can still occur, injuring workers and causing financial challenges. Knowing your legal rights and taking immediate steps after an accident can make a significant difference in securing compensation.

Injured on a construction site? Don’t handle your recovery alone. Contact our experienced NY construction accident lawyers today for a free consultation and ensure you receive the compensation you deserve. We serve victims of construction accidents across various locations in New York, including:

- Syracuse construction accident lawyer

- Rochester construction accident lawyer

- Binghamton construction accident lawyer

- Watertown construction accident lawyer

- Oneonta construction accident lawyer

Let us guide you through the legal process and help you secure the support and compensation you need for a full recovery.

Frequently Asked Questions After Construction Accidents

What Is the Difference Between an Incident and an Accident in Construction?

An incident is a near-miss that could have resulted in harm, while an accident is an event that causes actual injury or damage. Reporting both helps enhance site safety and prevent future incidents.

What Are the OSHA Regulations for Construction Site Safety?

OSHA regulations mandate employers to provide a safe work environment through fall protection, hazard communication, and regular safety training, reducing risks across construction sites.

What Role Does Insurance Play in Construction Accident Claims?

Insurance, such as workers’ compensation and liability policies, covers medical costs and lost wages, protecting employers from the financial impact of accidents.

Are Undocumented Workers Eligible for Compensation After a Construction Accident?

Yes. Undocumented workers are generally eligible for workers’ compensation benefits, as most states do not differentiate based on immigration status when it comes to workplace injuries.

How Do Weather Conditions Affect Construction Site Safety?

Weather conditions like rain, snow, or extreme heat can increase the risk of accidents by affecting visibility, equipment stability, and worker performance. Sites must adjust work schedules and equipment usage accordingly to ensure safety.

What Are Common Penalties for Safety Violations on Construction Sites?

Penalties for safety violations, often enforced by OSHA, can include fines, operational shutdowns, or even criminal charges for severe breaches, with repeat offenders facing stiffer penalties.

How Can Technology Improve Safety on Construction Sites?

Technological tools like drones, wearable safety devices, and AI can monitor conditions, detect hazards, and ensure adherence to safety protocols, significantly reducing the likelihood of accidents.